2013 08 01 CONSTRUCTION OF THE NEW ADDITIONAL 30,000 TPD CRUSHING SYSTEM IS COMPLETED. TESTING IN PROGRESS.

The Company reached a monumental milestone in the expansion construction process by completing its new additional 30,000 tpd crushing system, which is currently being tested. A ribbon cutting ceremony was held at CSH on August 1, 2013 for a test run on its newly completed 30,000 tpd stand-alone crushing facility.

Mr. Xin Song, the CEO and Executive Director of the Company, attended the commissioning ceremony for the crushing facility and reviewed the progress of the rest of the expansion. He commented, "We are very pleased with rapid execution of our expansion plans on both of our mines. We are proud to assure our shareholders that we are upholding our commitment to them on the expansion construction timeline. CSH mine has made a tremendous progress to complete the crushing facility ahead of the schedule by utilizing the talents of our people and the strengths of our major shareholder China National Gold. I would like to congratulate all members of our team at China Gold International Resources on this progress. I would also like to thank our board and shareholders, who continue to believe in and support us in our efforts.

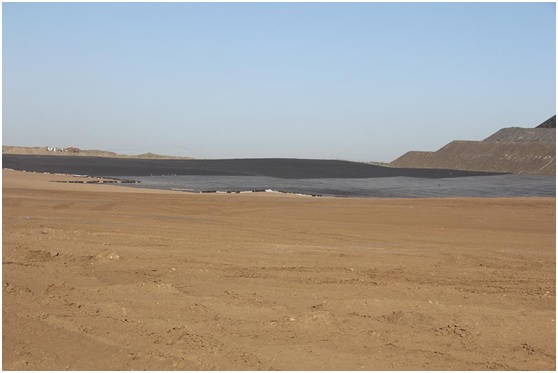

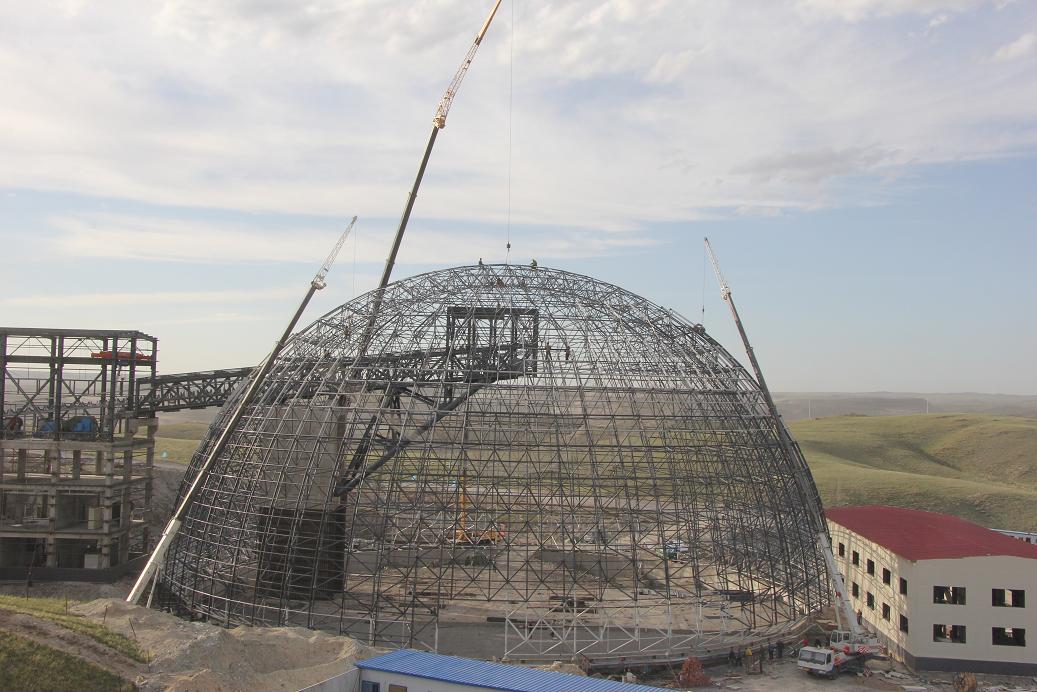

Panorama of the newly completed 30,000 tpd crushing system

Mr. Xin Song, CEO and Executive Director congratulates the Company on reaching a monumental milestone in the expansion construction and completing the crushing facility.

Crushing system commissioning ceremony

Crushing system feeding preparation

Crushing system feeding commences

|

CONSTRUCTION IN PROGRESS 2013 07 24

Crushing station: installation of the precipitator pipe is 95% complete; installation of air hose 100% complete; high-voltage power system has already been debugged and low-voltage power system is under debugging; auxiliary equipment is under testing; lighting is installed.

Ore storage: spherical grid painting is complete; installation of the precipitator pipe is 95% complete; installation of air hose 100% complete; low-voltage distribution cabinet electrified and low-voltage power system is under debugging; auxiliary equipment is under testing; lighting is installed.

Screening plant: the ground work of A-D axis is complete; installation of the precipitator pipe is 90% complete; installation of air hose 90% complete; water supply installation is 100% complete; water drain is 90% complete; high-voltage power system has already been debugged and low-voltage power system is under debugging; auxiliary equipment is under testing; lighting is installed.

Fine crushing station: the floor is finished; external wall, apron and ramp completed; installation of the precipitator pipe is 90% complete; installation of air hose 90% complete; water supply installation is 100% complete; water drain is 90% complete; high-voltage power system has already been debugged and low-voltage power system is under debugging; auxiliary equipment is under testing; lighting is installed.

Loading station: the ground work of A-D axis is complete; installation of the precipitator pipe is 90% complete; installation of air hose 90% complete; water supply installation is 100% complete; water drain is 90% complete; high-voltage power system has already been debugged and low-voltage power system is under debugging; auxiliary equipment is under testing; lighting is installed.

Leaching field: loess roller compaction is completed - 100,000 square meters; loess roller compaction of the emergency capacity lagoon excavation is completed - 5,000 cubic meters; loess roller compaction of the precious metal liquid pool excavation is completed - 3,000 cubic meters.

CONSTRUCTION IN PROGRESS 2013 07 10

Crushing station: there is no civil construction in this week, and the rest construction would be painting the operating room, constructing spron, etc.; backfilling field-leveling is 70% complete; steel structure is fully installed; main installation of gyratory crusher is complete; cable laying is complete, but not connected yet; dust removal system is 90 % installed.

Ore storage: indoor putty is complete; -9.00m ground concrete pouring is completed; spherical grid is closed and purlin installation is complete; color board installation is 30% complete; ore dumping chamber of heavy plate is completed; ore loading chamber of heavy plate is 80% complete; Cable laying is 70% complete, but not connected yet; dust removal system is 90% installed; power distribution cabinet is debugged by the cabinet manufacturers, and the automation cabinets unsettled.

Screening plant: Indoor plastering white is 70% completed; Class B fire door of the power distribution room is installed; steel window installation is complete; wall color plates is 70% installed; number 5 belt cohesive is complete, and cables is complete; air compressor is in place; dust removal system is 90% installed; power distribution cabinet is debugged by the cabinet manufacturers.

Leaching field: blasting of field-leveling in leach field is complete; earthwork constructing, backfilling, and tamping original-soil of field-leveling is complete; loess ramming of the leaching field is completed 450,000 square meters; ; HDPE geomembrane laying is completed 205,000 square meters; the construction of collector tube and gravel mattress begins.

CONSTRUCTION IN PROGRESS 2013 06 30

Screening plant: Indoor plastering is 70% completed; wall installation is completed; belt conveyor installation is 95% completed; #5 conveyor belt installation is about 95% completed; power distribution center installation is completed; wiring is completed except for the high-voltage cable.

Medium crushing workshop: plastering completed; enclosure wall tiling is completed; Concrete pouring in the 11.4m platform is completed; fire door installing is completed; wall color plates installed, purlin installing is 80% completed; cone crusher installing is 90% completed; precipitators are in place; #7 conveyor frame is ready for conveyor belt installation; four sets of the minecart installation are completed; cable laying is 50% completed.

Ore storage: indoor putty, spherical grid, purlin installation are in progress; ore dumping chamber of heavy plate is completed; ore loading chamber of heavy plate is in place and being installed; all cables installing is completed except for the high-voltage cable.

Elevated loading warehouse: Interior plastering is finished; wall insulation layer is finished; outdoor wall putty is 80% completed, interior paint is 70% completed; interior door installation is completed, wall color plates installation is completed, roof color plates will be installed. 9# conveyor installing is basically completed belt and finishing work is in progress; precipitator installation is 90% completed, power distribution cabinet installation is completed; cable laying is 90% completed.

#4 and #6 belt corridor: civil works are completed and installation of color plates in #6 belt corridor floor is 80% completed; installation of color plates in #4 belt corridor is 80% completed; #4 belt conveyor installed; #6 belt conveyor installation is completed, vulcanization bonding is completed, cable tray installation is completed.

CONSTRUCTION IN PROGRESS 2013 06 03

Ore storage: construction completed; four layers of spherical grid installation completed; dust remover and operating platform installation is complete, air hose installation is 90% completed; indoor water pipes installation is complete.

Crushing workshop: the interior plastering of the lubrication workshop and steel body basically completed, laying of 4.5 m steel platform completed, welding completed; four cone crusher bases are in place.

Elevated loading warehouse: 70% of interior plastering is completed; installation of steel windows is completed. Installation of all steel columns and steel girders for the 24.5 m platform is completed. 9 # belt conveyor installation is 50% complete; fabric machine installation is 60% completed.

Boiler Room: Concrete pouring in the slag removal area is completed, concreting in the coal belt gallery is 80% completed, 10 m platform ground pouring completed, and construction of chimney is 80% complete. Device is not admitted and will be admitted in 10 June.

CONSTRUCTION IN PROGRESS Q2, 2013